HV & LV Circuit Breaker Maintenance

Circuit breakers are essential to electrical power systems, providing reliable and safe operation by interrupting the current flow in case of a fault. Regular maintenance is necessary to ensure circuit breakers operate at peak performance.

At DCEC, we have the expertise and experience to provide high-quality maintenance services for High Voltage and Low Voltage circuit breakers. Our team of experts is equipped with the latest diagnostic tools and techniques to identify and diagnose any potential issues with your circuit breakers.

Our certified field technicians follow maintenance and testing protocols, including:

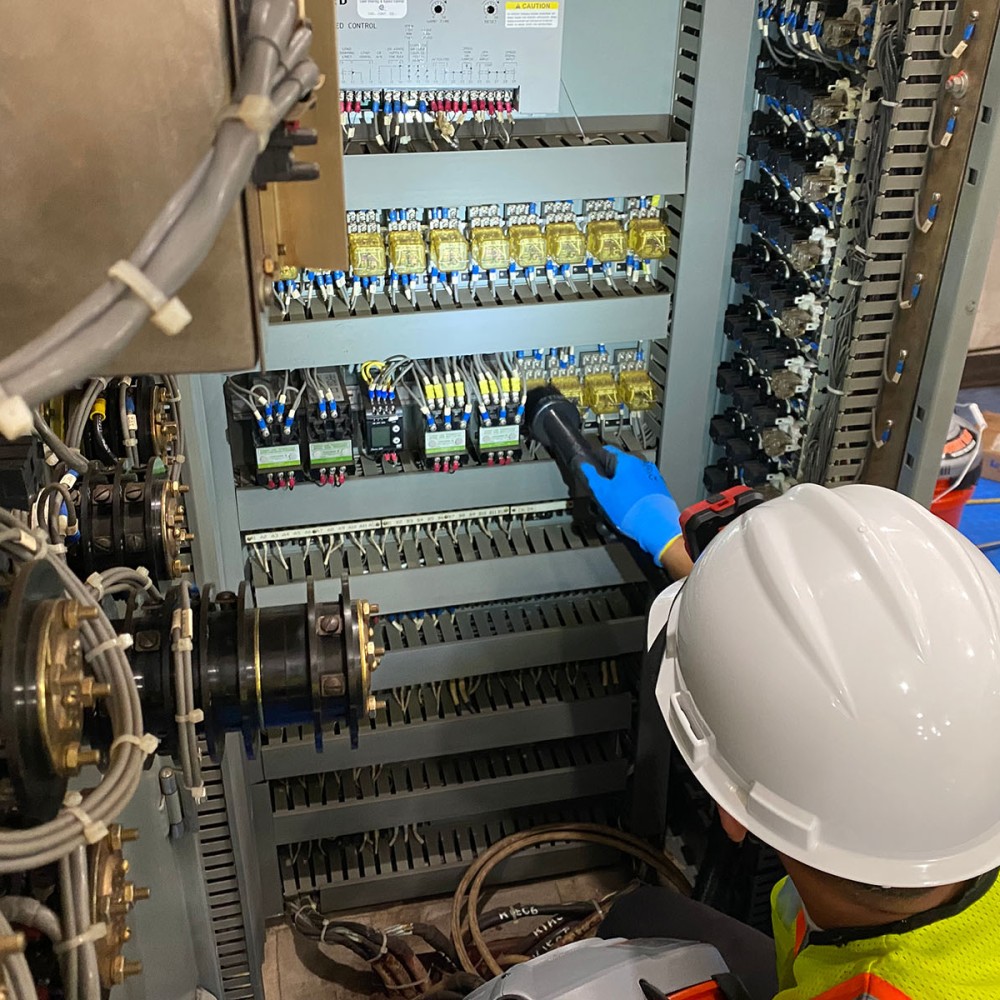

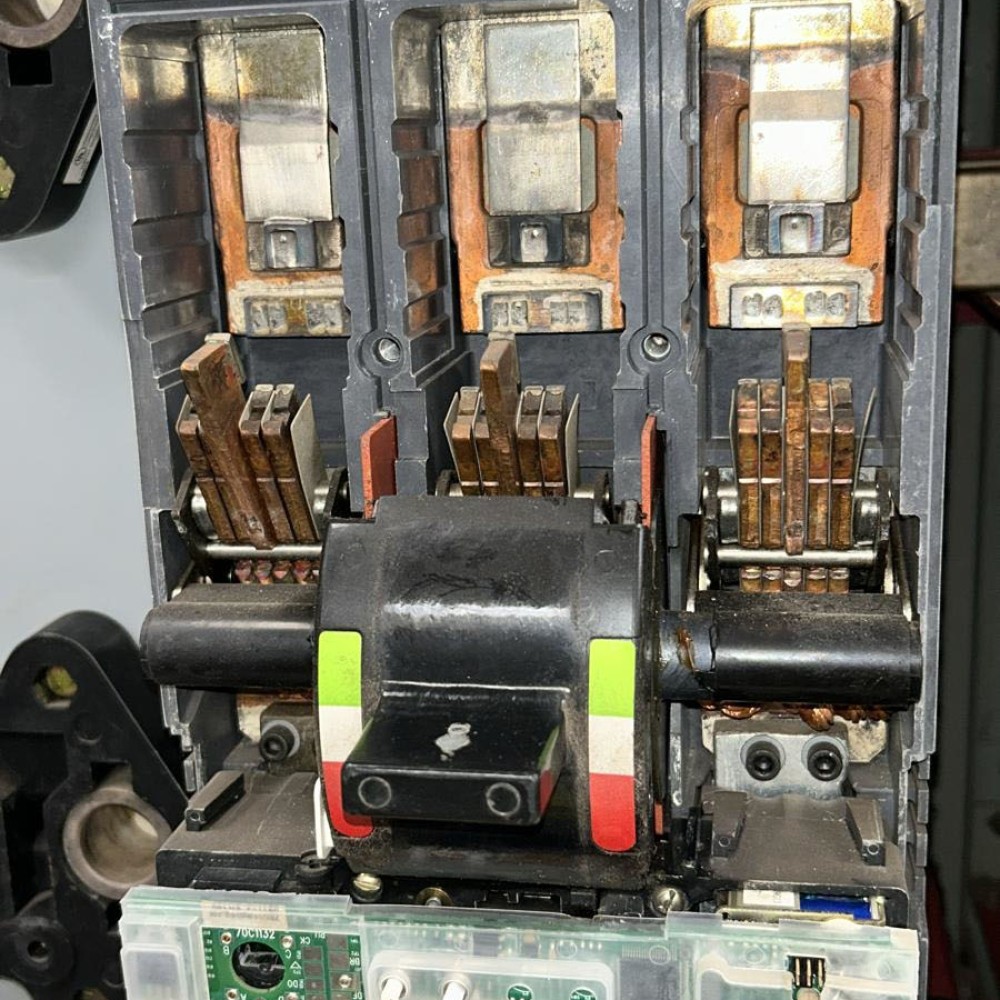

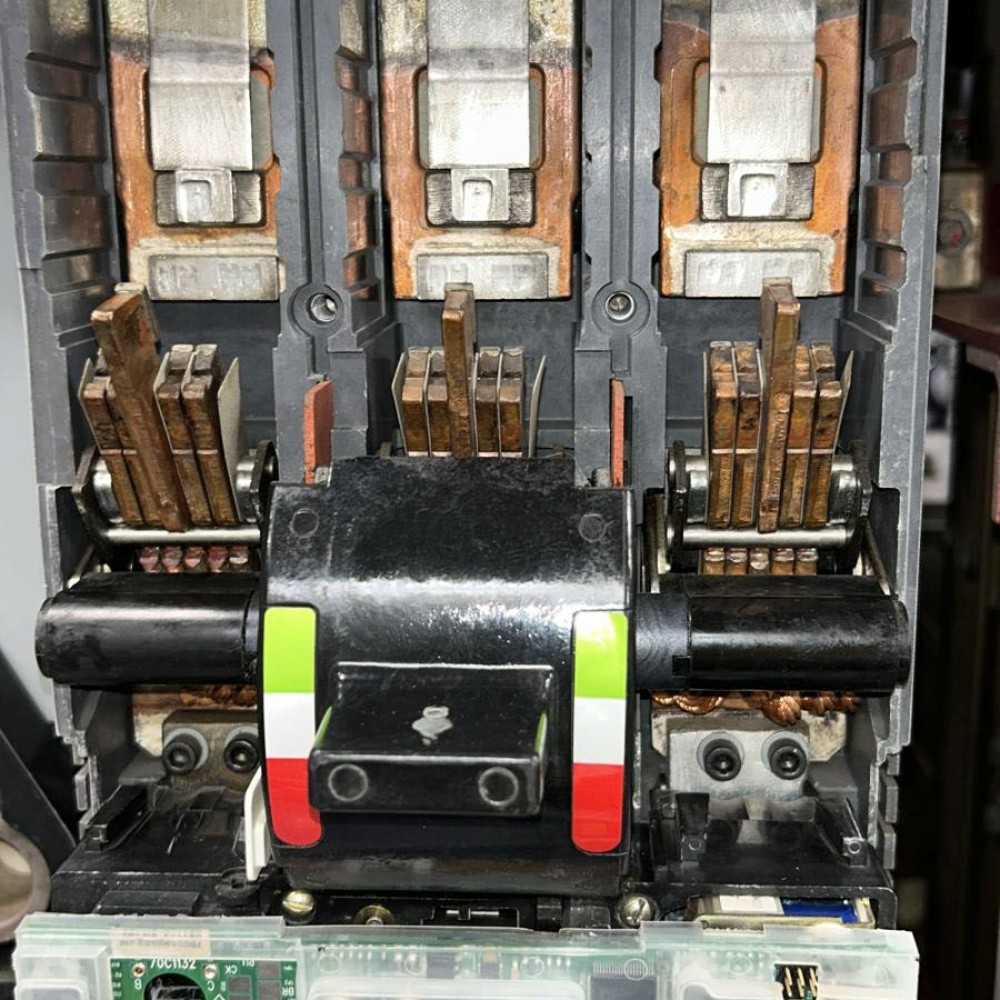

Visual Inspection: The first step in maintenance is a visual inspection. The circuit breaker is inspected for any signs of damage, wear, or contamination, such as loose or corroded connections, physical damage, or build-up of dirt or dust.

Cleaning and Lubrication: Moving parts within the circuit breaker requires proper lubrication. The lubrication points in the breaker are inspected, and any needed lubrication is applied.

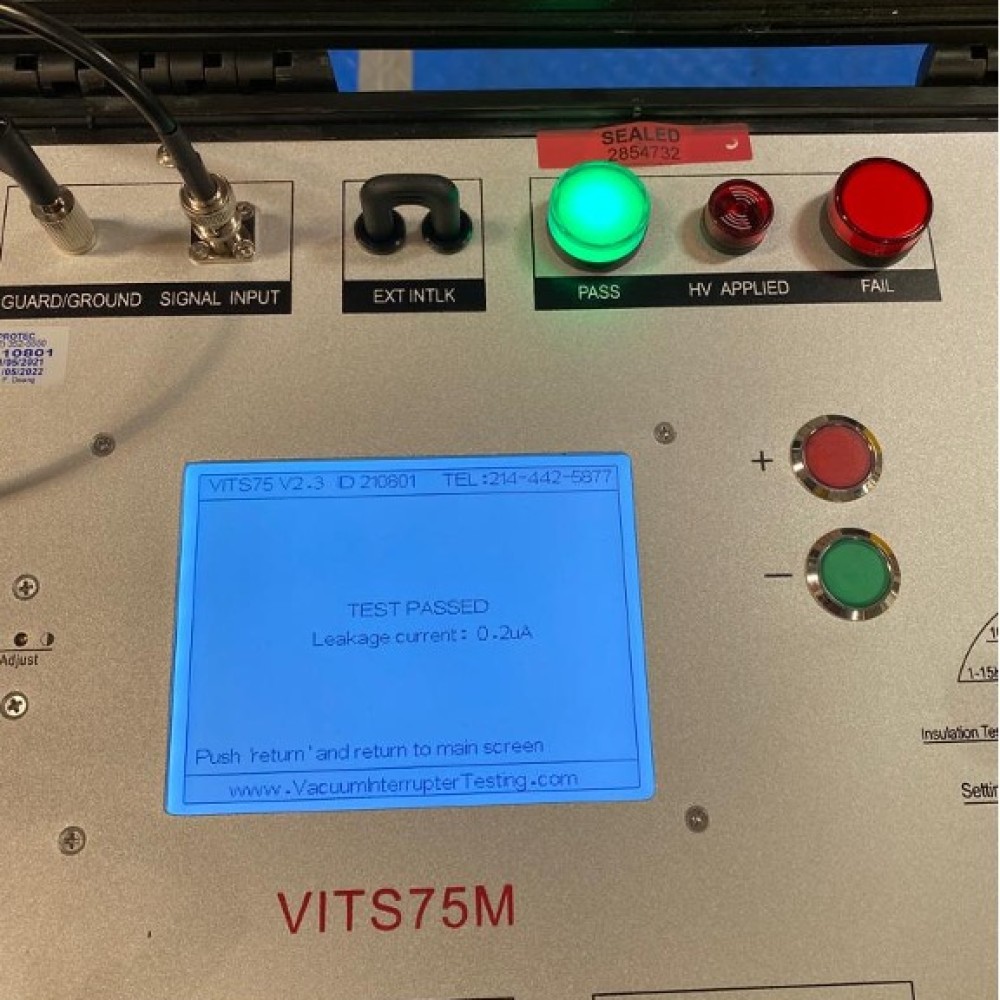

Mechanical and Electrical Testing: Mechanical and electrical tests are conducted to ensure the circuit breaker functions correctly. Some of the tests include:

• Open/Close Test

• Dielectric Withstand (HiPot Test)

• Contact Resistance Test

• Insulation Resistance (Megger Test)

• Primary and Secondary Injection Tests

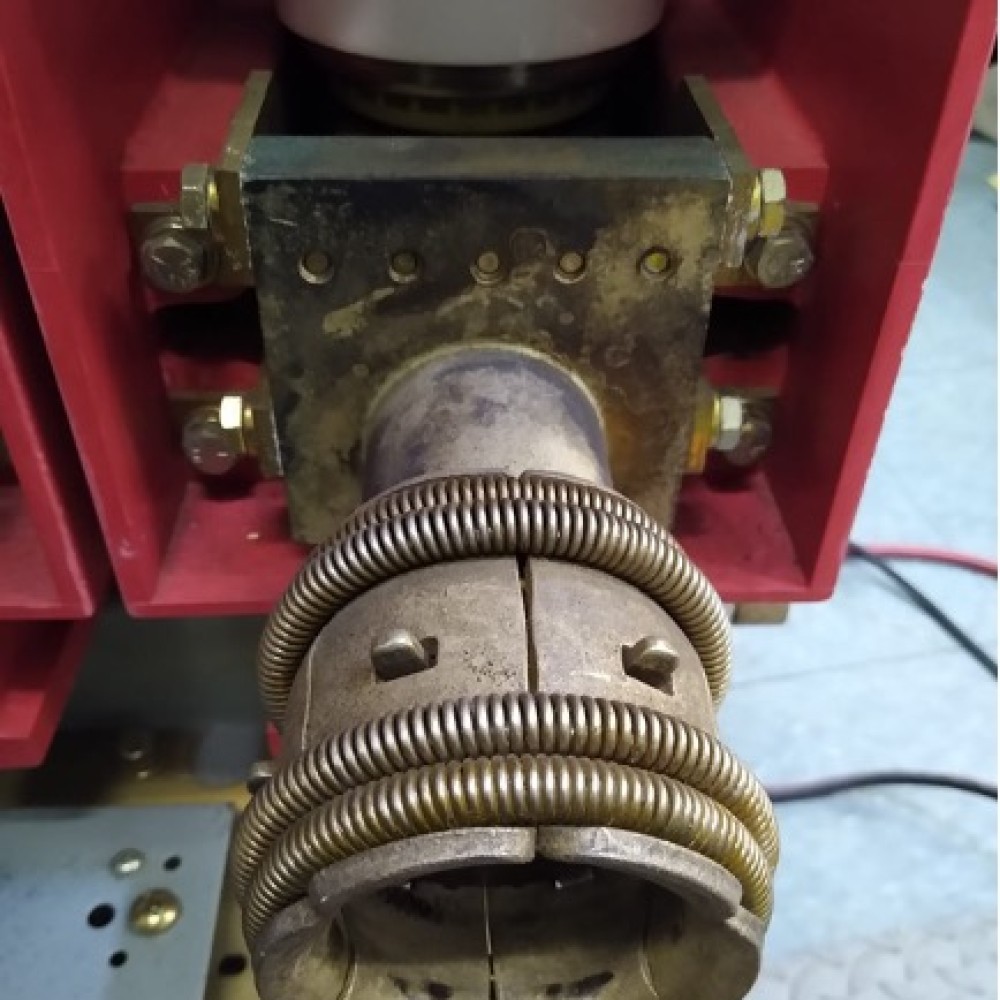

• Vacuum Bottle Integrity Test

• Operation Time

Upon maintenance completion, a Circuit Breaker Maintenance Report includes as-found/as-released conditions, electrical test results, discrepancies, and recommendations.

By performing regular maintenance on your circuit breakers, their lifespan can be extended, the risk of failures can be reduced, and they can be ensured to operate safely and efficiently.

Contact us today to learn more about our circuit breaker maintenance services and how we can help you keep your electrical power systems running smoothly.