Switchboard Retrofit and Maintenance

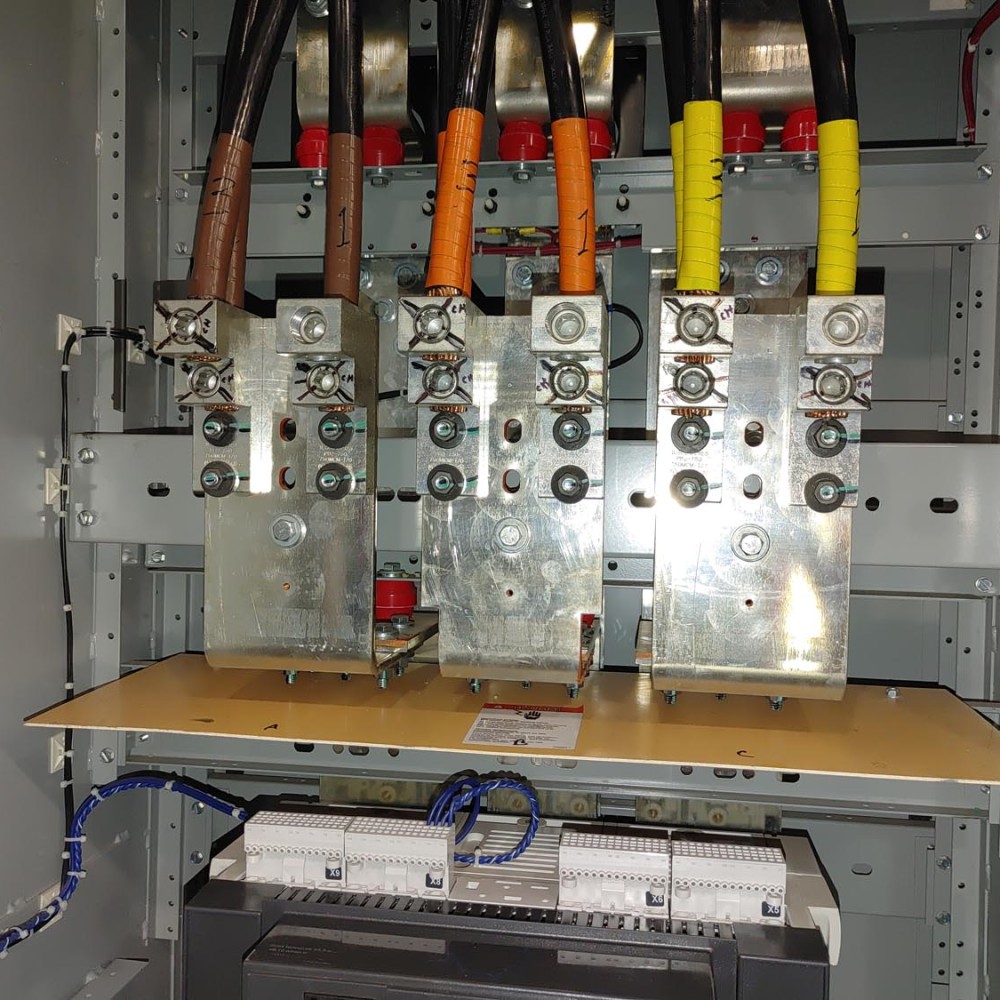

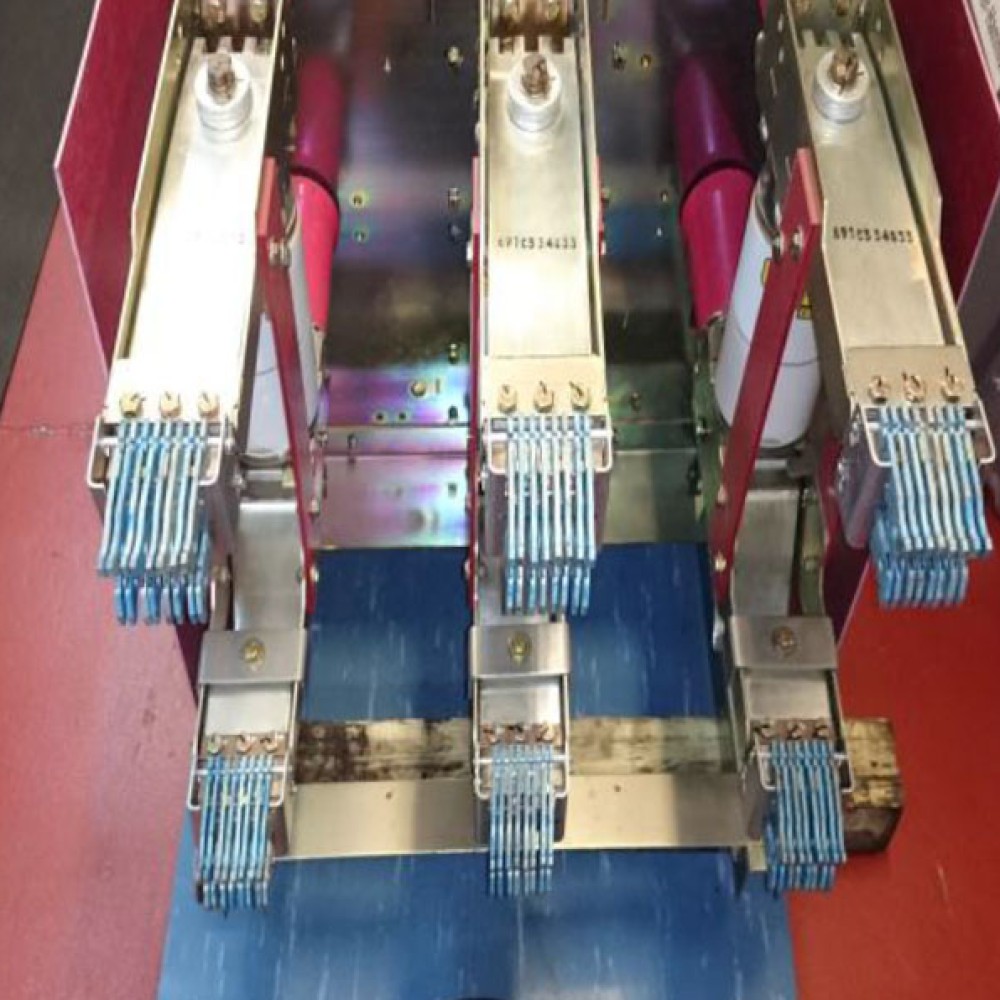

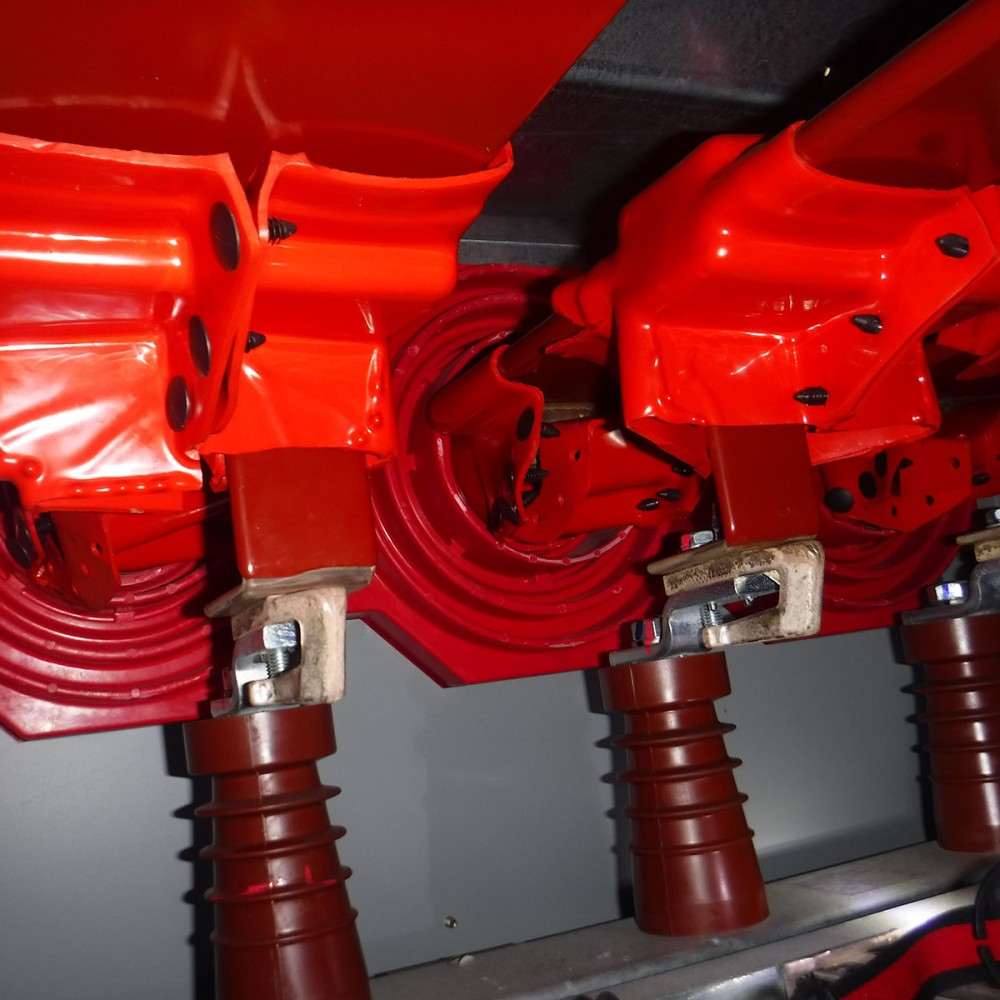

Switchgear retrofit refers to modernizing or upgrading existing switchgear to enhance its performance, reliability, and safety. It typically includes replacing outdated components, such as circuit breakers, relays, meters, or control panels, with newer, more advanced equipment. Retrofitting can improve system efficiency, reduce downtime, and ensure compliance with the latest industry standards and regulations.

Regular switchgear maintenance is crucial to ensure the proper functioning and longevity of the equipment. It involves inspection, testing, cleaning, and repairing or replacing faulty components. By conducting preventive maintenance, potential issues can be identified and resolved before they cause system failures or disruptions.

When selecting a supplier to accomplish scheduled Switchgear Maintenance or Upgrade/Retrofit, it's essential to consider their expertise, experience, certifications, and reputation in the field. It's also necessary to ensure they adhere to relevant safety standards and regulations.

DCEC field engineers and technicians specialize in HV and MV Switchgear design, control, troubleshooting, and maintenance. Our maintenance protocol includes:

- 10-point visual inspection

- Cleaning and grooming of cabinets

- Torque check of the busbar joints

- Maintenance of breakers, switches, and control panels

- Insulation Resistance test of switchgear

- As-found/Tasks Performed report

DCEC excels in the design, fabrication, commissioning, and start-up of switchgear, load centers, motor control centers, and control panels for applications such as:

- Marine

- Utility power

- Oil and gas

- Critical power facilities

- Among others

Do you have a project in mind? Let our Design team come up with an intelligent solution. We’ll get it done.