Thermographic Survey

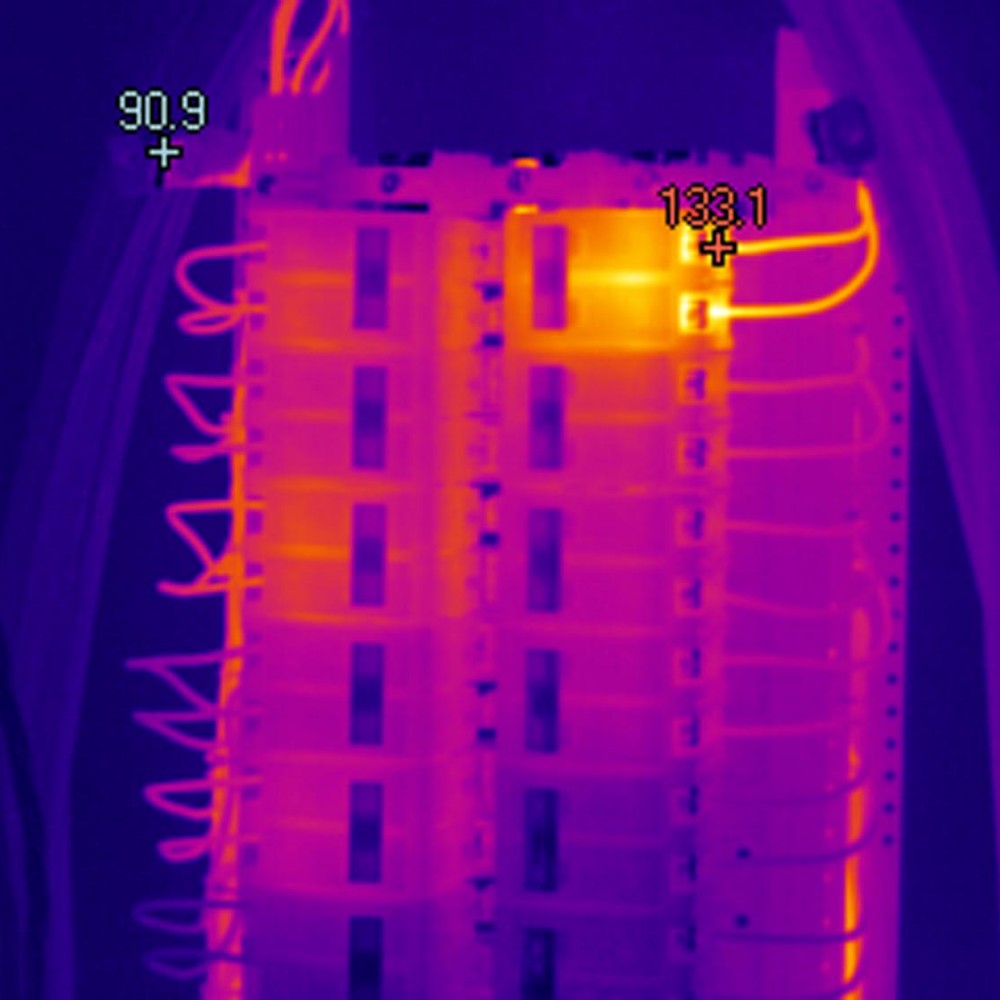

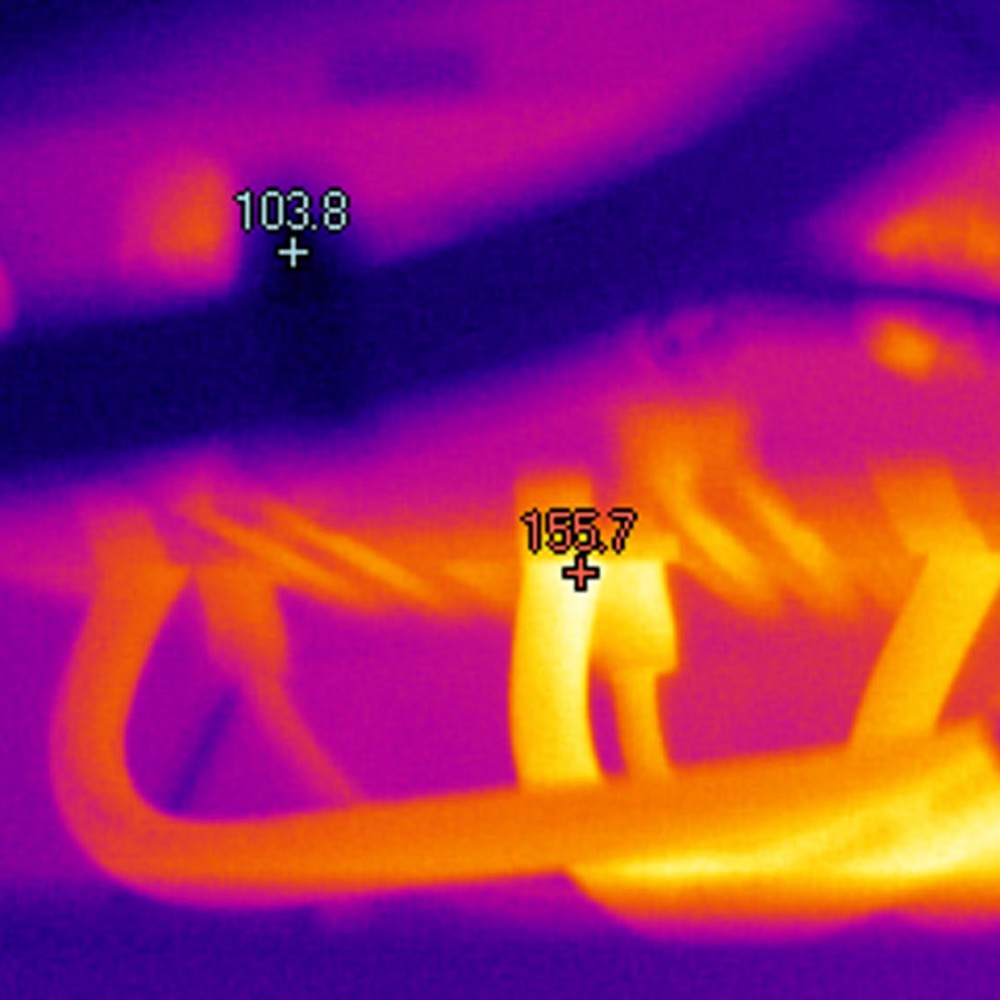

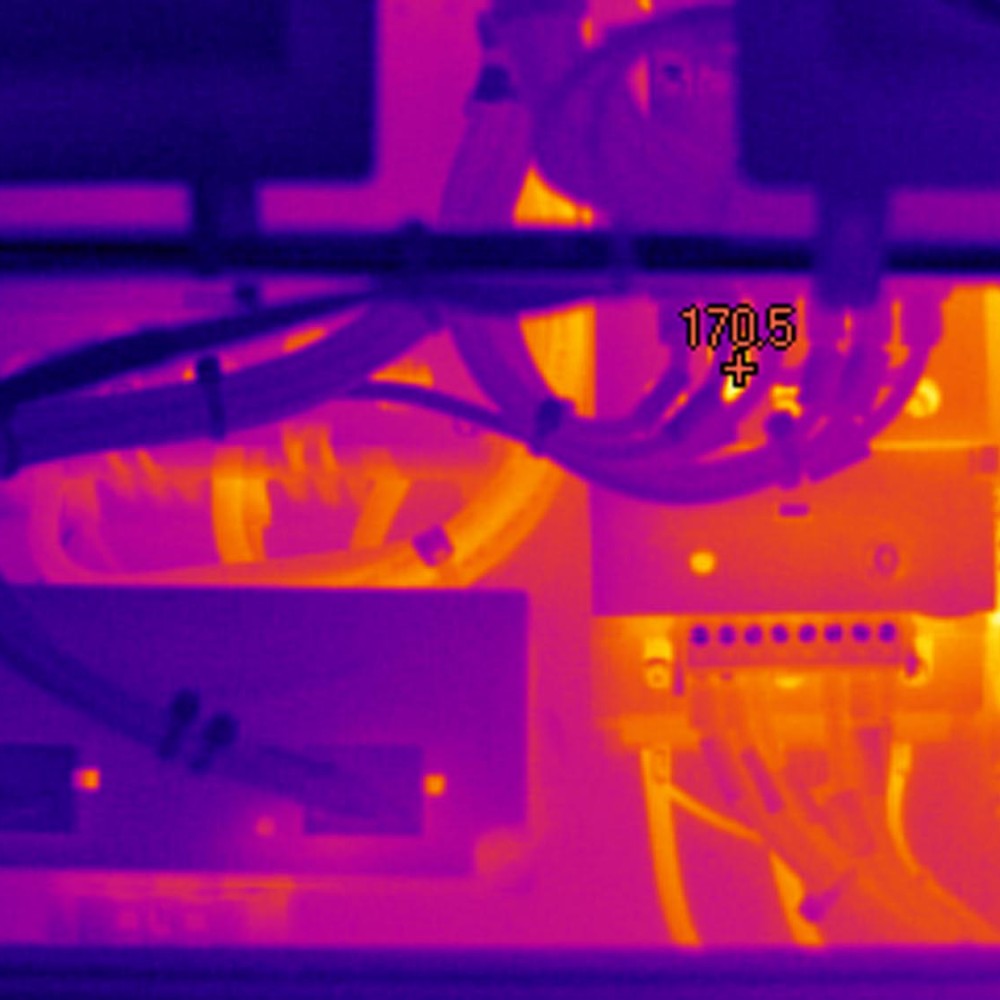

A thermographic survey of electrical systems, also known as an infrared electrical inspection, is a non-destructive testing technique to detect and locate anomalies in electrical equipment such as switches, transformers, and circuit breakers.

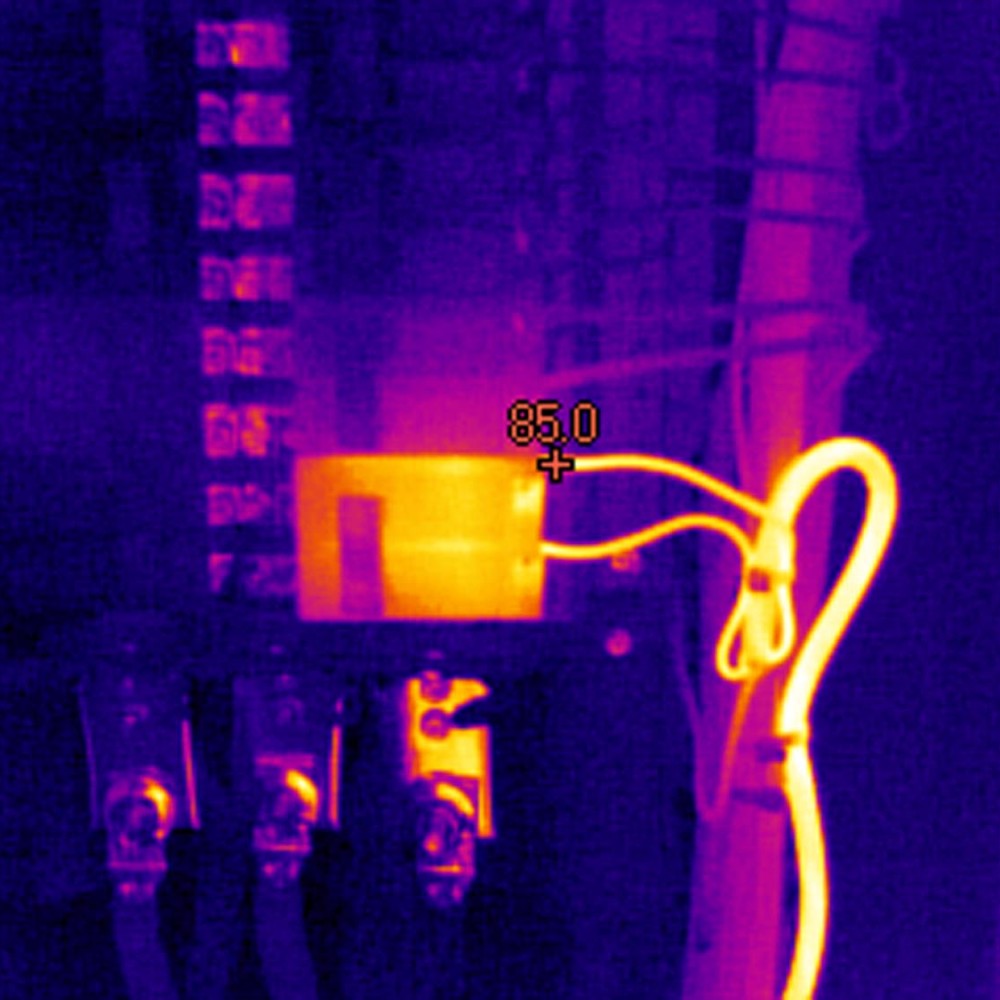

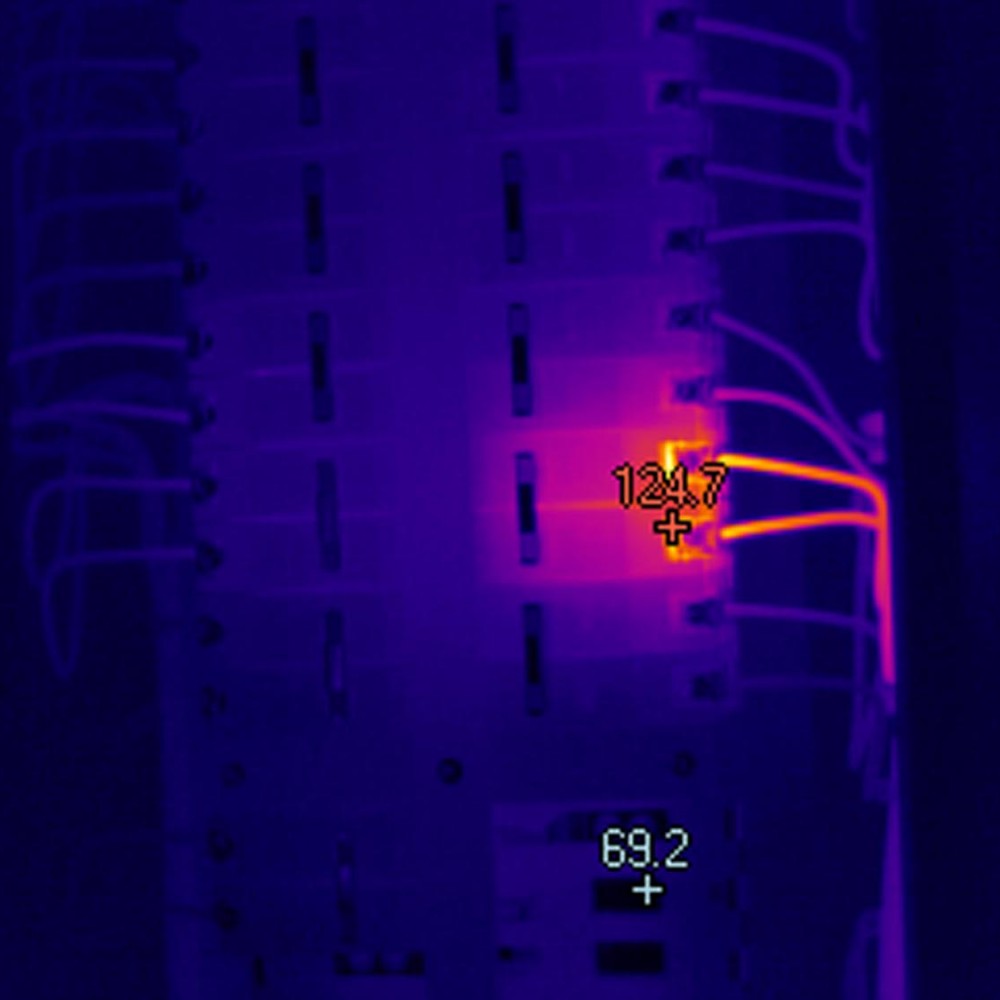

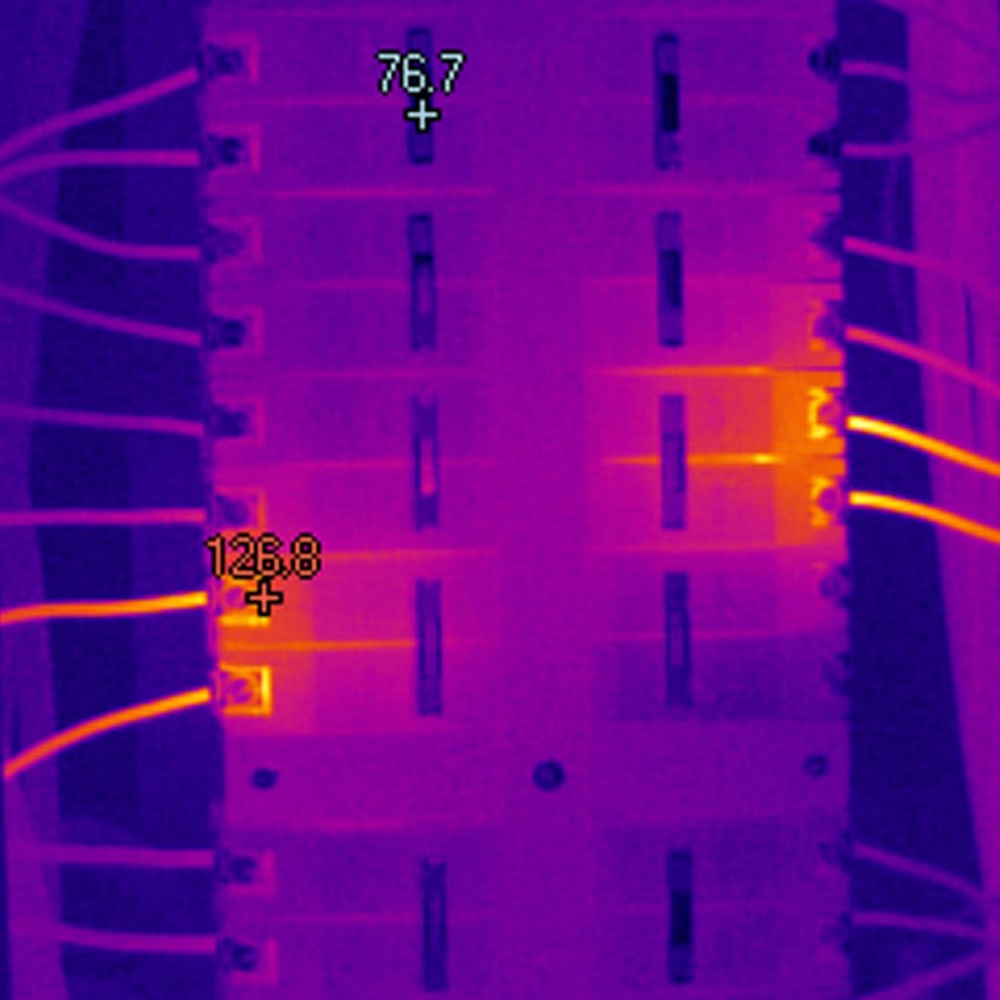

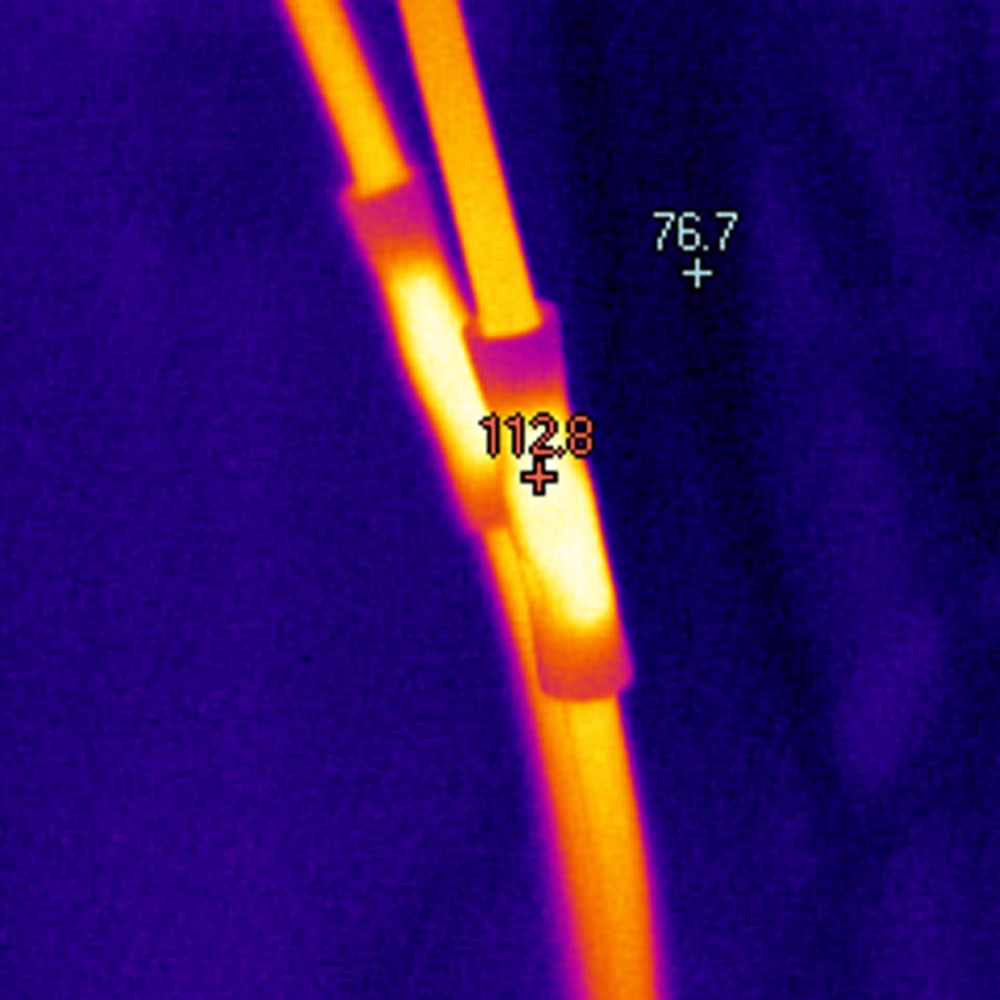

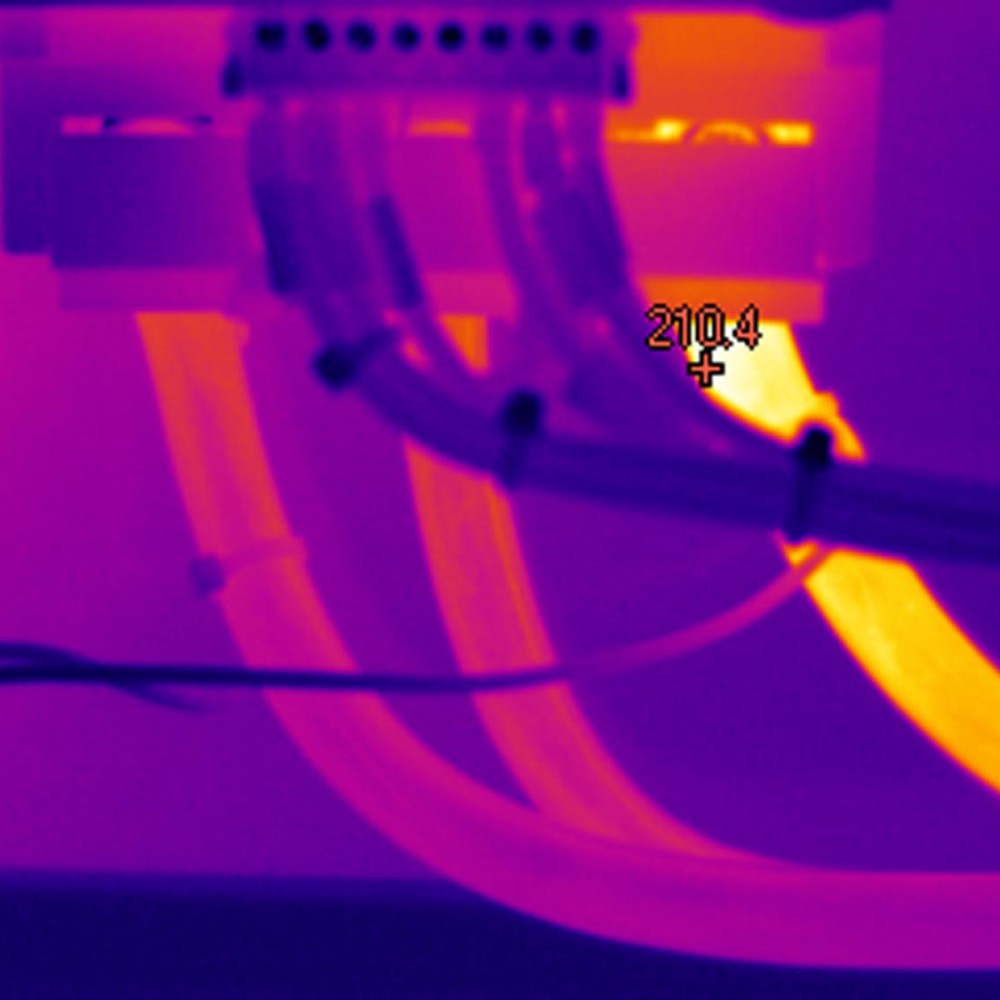

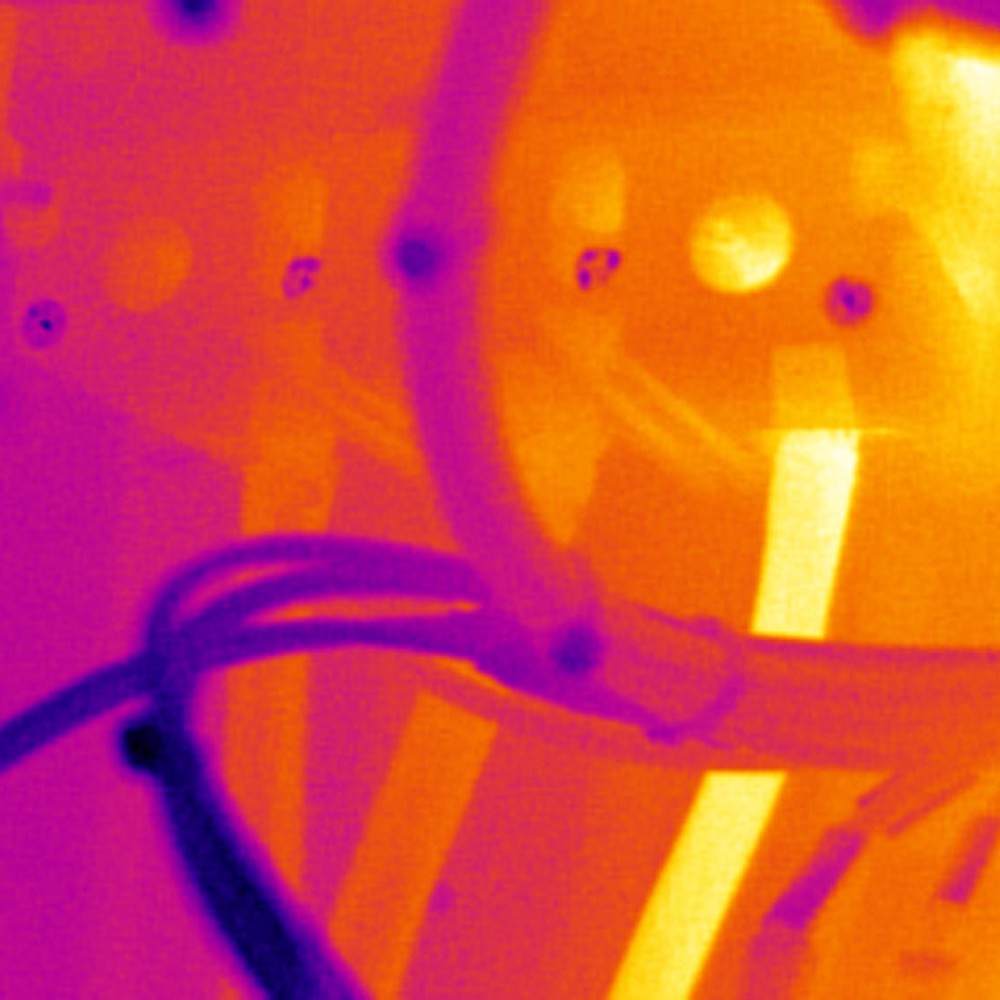

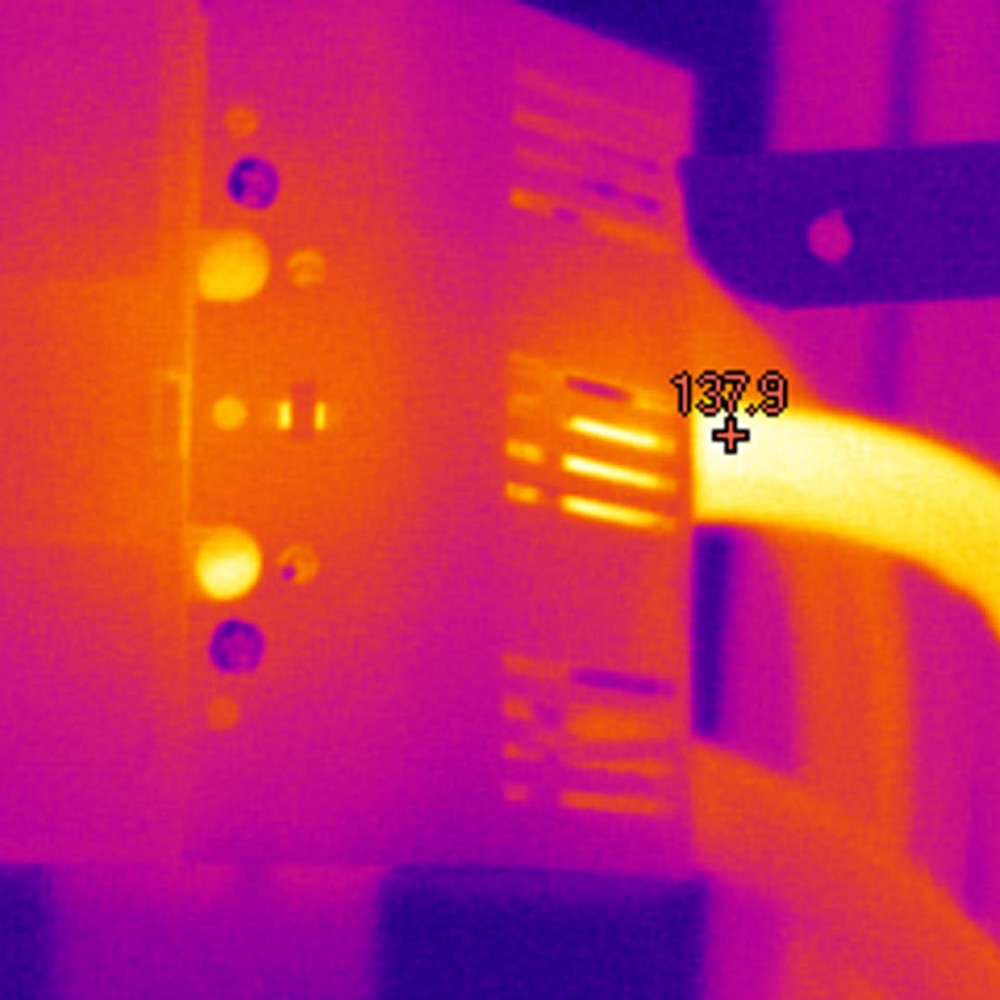

During a thermographic survey, a qualified technician uses an infrared camera to capture the equipment's images and show the temperature distribution of the equipment's surface. As electrical equipment heats up during regular operation, the camera can detect any areas where the temperature is higher than expected. These hot spots can indicate potential issues, such as loose connections, overloaded circuits, or faulty components.

Thermographic surveys can help identify problems such as equipment failure, power outages, or even fires before they cause serious issues.

Our Level II Certified Thermographers’ expertise, combined with a team of back-office engineers who produce Quantitative Reports in real-time, allows the client to correct critical faults found during the inspection based on our recommendations. We thermally reinspect those targets upon repairs to ensure temperatures return to normal operating parameters.

By regularly performing thermographic surveys, our clients can increase the reliability of their systems, reduce downtime and maintenance costs, and improve overall safety.

Let’s schedule your following thermographic survey today!