PLC Surveys, Troubleshooting, and Programming

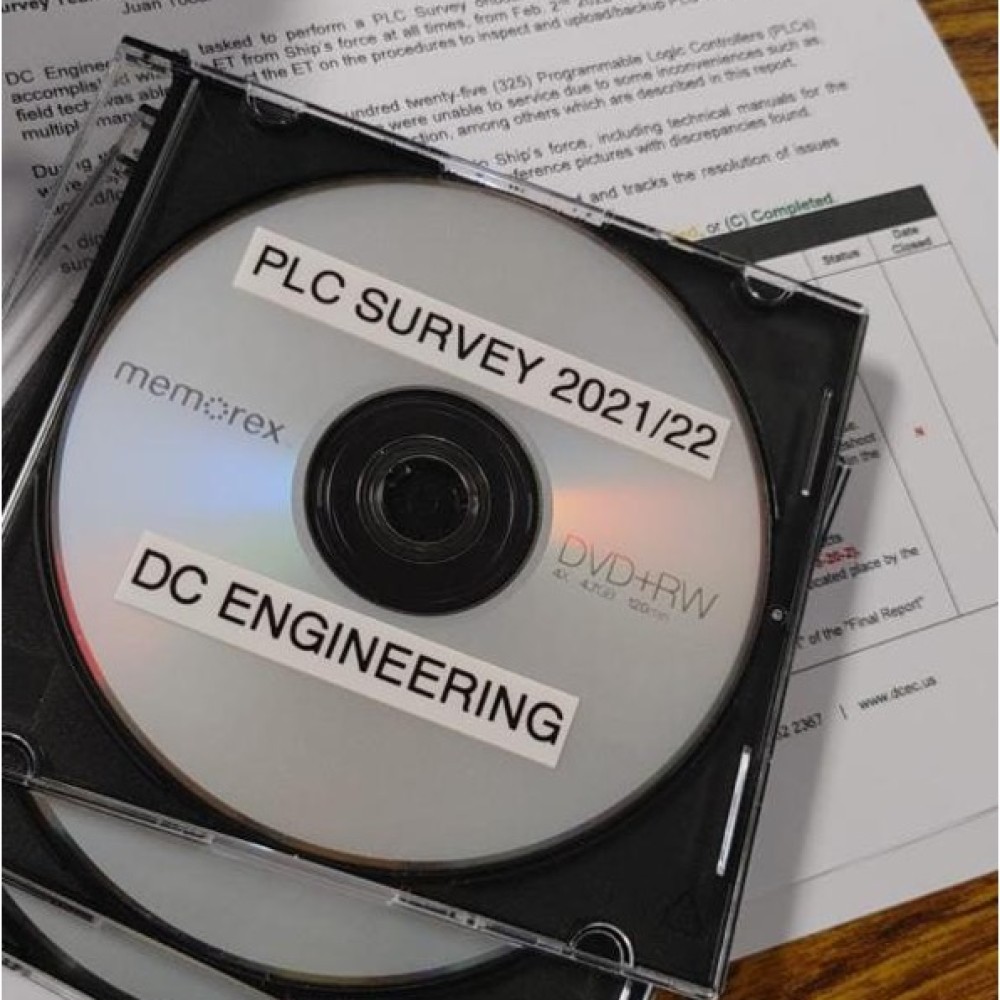

A PLC survey evaluates and analyzes the existing Programmable Logic Controllers (PLCs) in an industrial control system. The survey helps identify potential issues and areas for improvement, such as outdated hardware or software, inadequate communication protocols, or insufficient programming.

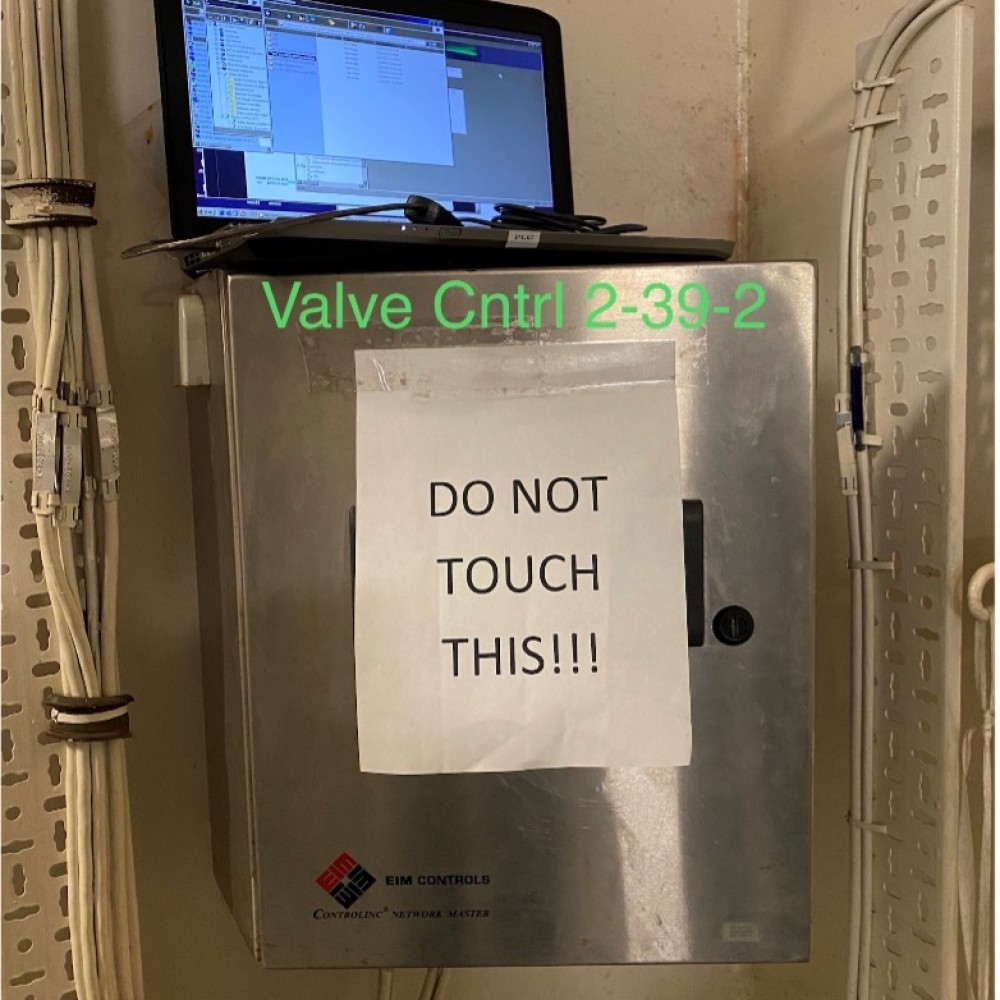

DCEC field engineers take the following critical steps during a PLC survey:

- Identify the PLC models and their configuration

- Review the programming and documentation

- Check the wiring and electrical connections

- Check for any fault or error messages in the system

- Test the inputs and outputs of the PLCs

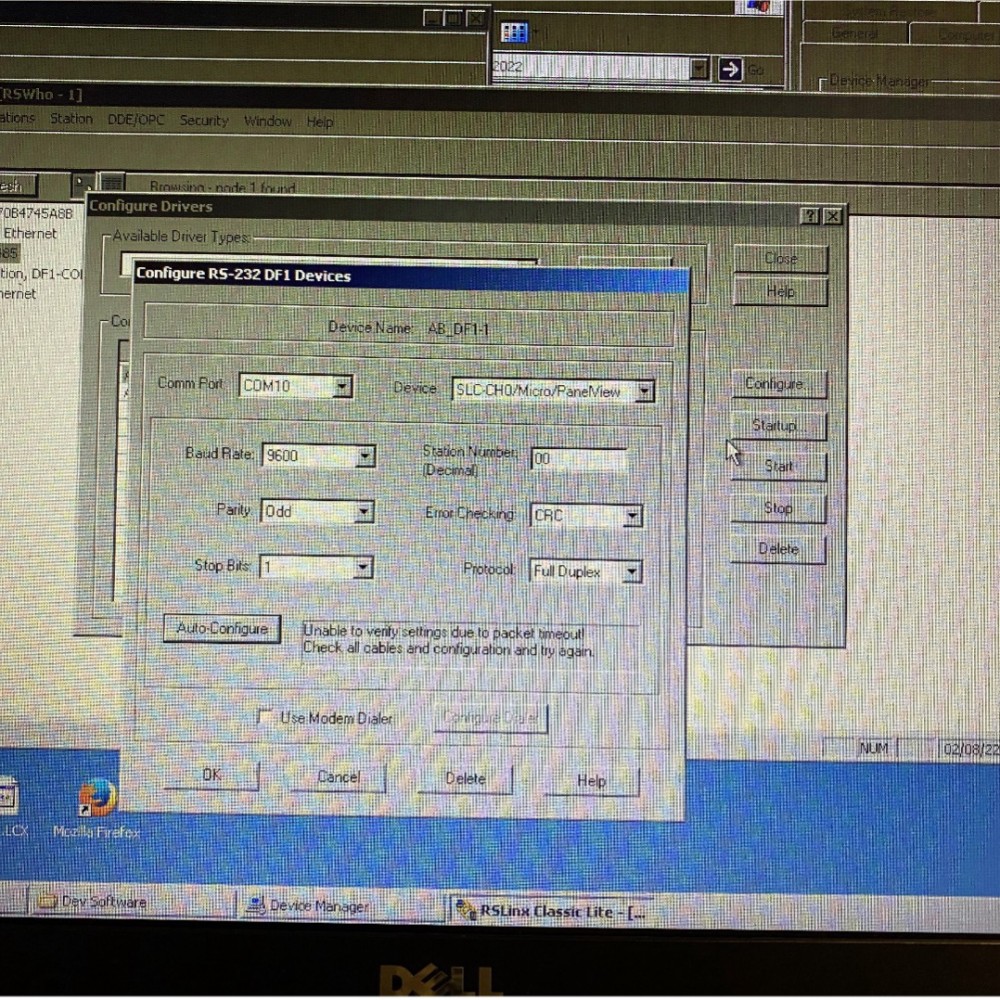

- Check the communication protocols

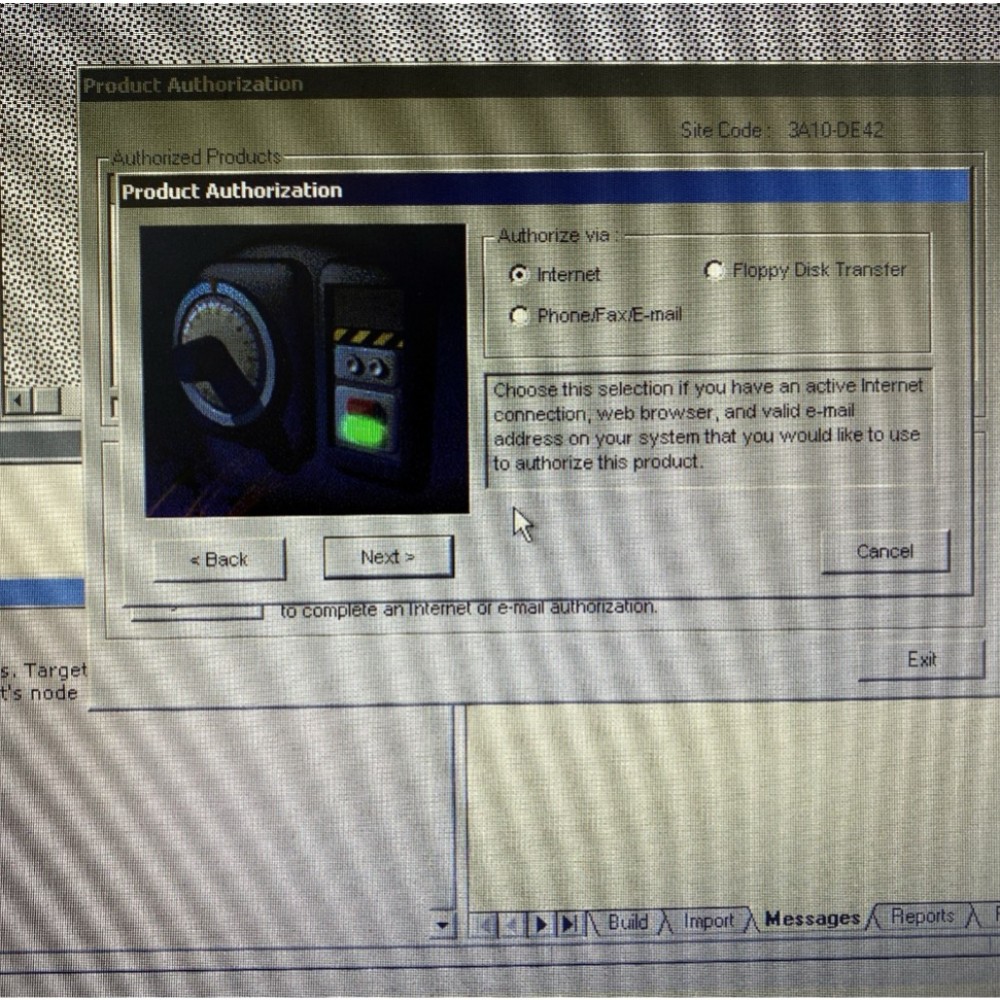

- Review the maintenance and backup procedures

Over 15 years of experience in Automation and Control Design and Manufacturing allow us to correctly identify and resolve issues such as malfunctioning I/O devices, faulty wiring, software bugs, hardware failure, and communication errors while following safety procedures and protocols. Upon survey completion, our clients receive a comprehensive service report, including all equipment surveyed and associated PLC programming.

A PLC survey is critical to maintaining an industrial control system, so if you have not conducted a PLC survey recently, it's time to take action. We are ready to inspect your PLCs. If any potential issues are identified, we will make necessary improvements to ensure your system's reliability and efficiency.